Pyrolysis is not a ‘future-proof’ solution in the battle against plastics, insists Zero Waste Europe. The group argues in a new report that relying on the chemical process creates a ‘leaky loop’ rather than a circular economy.

‘Even in the best scenario, only 2% of today’s plastic waste fed into pyrolysis will actually make the round trip into the steam cracker and then be recycled,’ writes Zero Waste Europe (ZWE). Plastic waste

Furthermore, it argues, the process produces new, unwanted, and toxic hydrocarbons. ‘All plastics, though notably the polyolefins which are identified as ideal pyrolysis feedstocks, do not simply revert back to the precursor material from which they were formed,’ the report says.

‘Instead, they produce a wide variety of products due to aggressive chemical substances, known as free radicals, splitting from the plastic and re-combining in unwanted forms.’ These pyrosynthetic hydrocarbons lower the product oil yield and impair its quality, it adds.

High contamination

ZWE believes ‘chemical recycling’ is not the answer for difficult-to-recycle plastic waste streams. Highly mixed, unwashed or difficult-to-recycle plastic waste streams, such as automotive shredder residue and computer casings, result in a pyrolysis oil with substantially increased levels of contamination. Plastic waste

‘The universal laws of physics and chemistry that govern pyrolysis are unlikely to change because of marketing pressure,’ the report states. ‘Decision makers would be sensible to accept that pyrolysis is not the wonderful miracle they need merely because no other back-end solution exists.’

It claims the laws of thermodynamics dictate that the most sensible solution to minimising plastic waste lies in upstream intervention. ‘This means putting investment into making plastic products less complex, less contaminated, and more recyclable,’ the report concludes.

New batteries for electric cars and wearables, backed by multi-million US$ funding, are both fire resistant and flexible

Batteries are regarded as crucial technologies in the battle against climate change, particularly for electric vehicles and storing energy from renewable sources. Anthro Energy’s novel flexible batteries are presently available to wearable manufacturers and could be employed in a variety of areas, including electric cars and laptops.

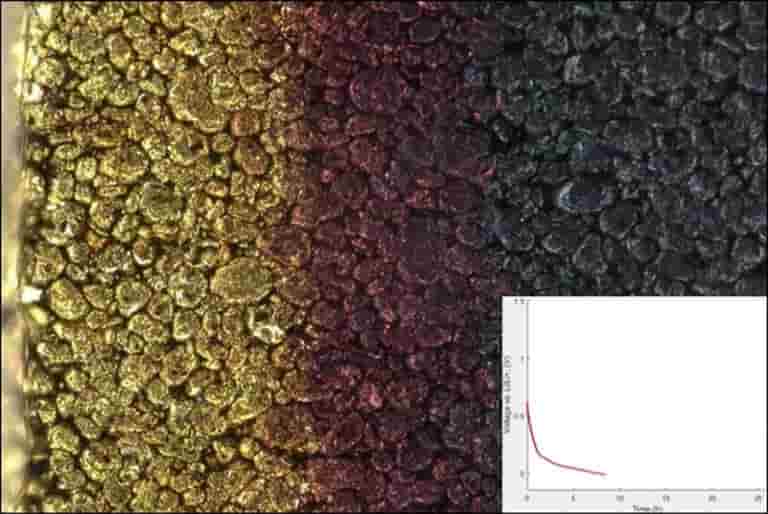

The innovative batteries score well in fire safety, thanks to new materials and design features that eliminate internal and external mechanical safety risks like explosions. Many of today’s batteries, such as lithium-ion batteries, contain a flammable liquid as an electrolyte.

Anthro Energy’s David Mackaniac and his team have created a flexible polymer electrolyte that is malleable like rubber. The new technology provides increased design flexibility for use across a range of devices, with adaptable shapes and sizes to suit specific applications.

The batteries are highly durable, capable of enduring tens of thousands of bending cycles without any decrease in performance. Plastic waste

Nylon demand falls across major end-uses; China exports pressure margins – AdvanSix CEO

“Overall, we see demand declines across most key end markets, leading to further margin compression in the industry,” Kane said.

In North America, the higher interest rate environment is unfavourably impacting building and construction end markets, she said. Plastic waste

The high rates are also impacting consumer spending, with implications for nylon in packaging applications, she said.

However, auto has been a more “resilient” end market for AdvanSix, with the recent US auto worker strikes only modestly impacting engineered plastics demand, she said.

Meanwhile, low-priced imports are creating “competitive intensity”, she said, noting in particular exports from China.

“We are seeing China’s global nylon exports reach all time-highs” amid that country’s slower economy, thus putting pressure on nylon prices and margins, she said.

The company expects nylon industry margins to remain at “trough levels” through year-end, due to the unfavourable supply and demand conditions, she said.

With the softness across the key nylon end market in North America, AdvanSix would “continue to leverage various sales channels to meet demand where it exists, including a higher share of exports”, added chief financial officer Michael Preston.

On the positive side, underlying agriculture industry fundamentals are expected to remain favourable, boding well for ammonium sulphate (AS). Plastic waste

AS is a by-product of AdvanSix’s integrated nylon production process.

In North America, “the underlying fundamentals continue to support firm fertilizer demand, moving forward”, Kane said, adding: “Our current order book is robust”.

As for acquisitions, “accretive M&A has always been part of our framework” and the company continues to evaluate opportunities, she said, adding: “This is an interesting time” for M&A.

She was responding to an analyst on the call who suggested that AdvanSix, with its healthy balance sheet, should have the opportunity to expand with “bolt-on” deals in chemical intermediates, specialties or other products. Plastic waste

Bloomberg Asks Why Electric Cars Today Are So Huge

The UK has a long tradition of small cars, exemplified by the original Mini but including a gaggle of MGs, Triumphs, Humbers, Hillmans, Cortinas, Austins, and the like. Mostly they were small because raw materials were scarce after World War II, but also because Britain taxed cars based on horsepower. Smaller cars were lighter, which means they could make do with less powerful engines. While all of that is true historically, it does not explain why most electric cars sold in the UK today are so big and heavy. Plastic waste

Bloomberg correspondents Olivia Rudgard and Kyle Stock spent some time driving around London behind the wheel of an Ora Funky Cat. At just over 4 meters (13 feet) in length, the four door, five passenger hatchback proved to be an able and efficient vehicle for use in that environment. For some perspective on size, the Maxda MX5 — known as the Miata in North America — measures 12.8 feet in length. [Note: The Funky Cat appears to be very similar in size to a first-generation Nissan LEAF.]

Of the 72 electric cars available in the UK, nine have batteries with a capacity under 50 kWh. (Just two EVs in the US have such small batteries.) Between 2013 and 2022, new sales of every type of car declined in the UK — except SUVs, whose sales have risen 75% over that period according to the Society of Motor Manufacturers and Traders (SMMT). In August, tests by Which?, a consumer group, identified 161 cars too big for standard UK parking spaces, up from 129 in 2018. Plastic waste

Small cars like the Fiat Punto and the Ford Fiesta have been discontinued and replaced with SUVs in recent years, says Ralph Palmer, UK electric vehicles & fleets officer at Transport & Environment, which tracks the new and used car markets. “They’re seeing that there are great profit margins to be made from selling a massive SUV for a far higher margin, but selling fewer of them,” he said.

Electric Cars — How Much Is Enough?

This shift in the marketplace, especially when it comes to electric cars, is creating a dearth of options for commuters looking to buy only as much car as they need. The Ora Funky Cat with its 48 kWh battery has a range of 320 kilometers (about 200 miles). As Rudgard and Stark discovered, that is more than ample range for urban driving. After a weekend of shopping and hauling furniture from IKEA, they still had nearly a 50% state of charge remaining in the car’s battery. The car’s dimensions mean it is closer in size to those iconic British cars of old, which is a plus in crowed urban environments where a car can be more of a logistical nightmare than a convenience. Plastic waste

Sage Automotive Interiors Partners With US Startup NFW

Sage Automotive Interiors has partnered with Peoria, Ill.-based startup, NFW, a producer of a plastic-free, plant-based leather alternative for car interiors. This strategic partnership between Sage Automotive Interiors, part of the Asahi Kasei Group, and NFW, a leading global provider of innovative and functional materials for the automotive interior — enables another major step to support global automotive OEMs in reducing the environmental burden of the automobile lifecycle. Plastic waste

NFW was founded in 2015 and has developed the only platform capable of producing precision-engineered, all-natural (zero plastic) leather, foam, and textiles to replace animal and petrochemical-based materials. MIRUM®, the company’s patented leather alternative, is made from natural rubber, natural fibers, plant oils, natural pigments, and minerals. MIRUM is bio-neutral and can be safely returned to the Earth or recycled by NFW at the end of its lifetime. The material offers superior durability and quality that can replace traditional animal-based or synthetic leather products without the use of any polyurethane or other coatings.

Sage is engaged in the development, manufacturing, and sales of innovative functional materials used in automobile interiors globally. Since its acquisition by Asahi Kasei in 2018, Sage has continued to strengthen its business activities in Europe and China through mergers and acquisitions in parallel to expanding its lineup of growth-potential materials such as suede and synthetic leather. Plastic waste

As one of the leading global suppliers in the car seat fabric market, Sage has a strong presence among automakers and suppliers.

Luke Haverhals, CEO and founder of NFW, said: “Over time, our partnership with Sage will allow consumers to apply the same decision-making process that they use in their homes, in their cars as well — the most sustainable option will be available to them. The kind of impact that matters to the planet has to happen at scale, not just around the edges.”