rPET granules – In 2022, there was a reduction of 19 kilograms per person in municipal waste 05-02-2024 - Arhive

rPET granules

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Catalysis R&D Agreement Between Maire and Polimi

Maire’s subsidiary NextChem and the Energy Department of Polytechnic University of Milan (Polimi) have inked a five-year pact focusing on crafting groundbreaking catalysts for eco-friendly chemistry and the shift towards sustainable energy. Spearheaded by Professor Isabella Nova, the collaboration delves into innovative catalyst research, process modeling, and reactor geometry.

NextChem, a part of the Italian Maire conglomerate, aims to fortify its role in the energy transition and sustainable chemistry domain through this alliance. rPET granules

Catalysts, pivotal in expediting chemical reactions by lowering activation energy barriers, hold paramount importance in this endeavor, constituting 90% of chemical processes.

This initiative not only underscores NextChem’s commitment but also seeks to harness the brightest minds via synergies between academia and industry. It builds upon existing collaborations, such as the Chemical Projects Engineering and Management chair established in 2017.

For Maire’s CEO Alessandro Bernini, this agreement signifies a renewed and reinforced bond between the conglomerate and Polimi.

He emphasizes the historical connection, tracing back to Giulio Natta’s Nobel-winning studies on polypropylene, as emblematic of fruitful industry-academia collaboration fostering innovative solutions for the future. rPET granules

Itelyum and Plasta Rei revolutionize recycling, turning food packaging into rPET granules

Itelyum and Plasta Rei have pioneered a revolutionary approach to recycling, converting food packaging waste into top-tier rPET granules, thus advancing environmental sustainability significantly. Collaborating, Itelyum, a division of Stirling Square Private Capital, and Plasta Rei, an expert in recycling technology, aim to redefine the standard for recycling food packaging waste, producing 100% recycled polyethylene terephthalate (rPET) granules. This partnership not only signifies a remarkable technological leap but also a crucial step toward sustainability. rPET granules

Revolutionizing Recycling Plasta Rei’s chemical recycling process retrieves over 95% of PET waste, generating high-quality rPET granules that maintain their integrity through multiple recycling cycles, in contrast to traditional mechanical methods. The resulting rPET matches virgin PET in quality, revolutionizing recycling and offering sustainable packaging options.

Environmental Impact and Sustainability By converting food packaging waste into virgin-like rPET granules, the collaboration reduces reliance on virgin plastics, curbing plastic pollution and preserving petroleum resources. Studies underline the environmental sustainability of PET depolymerization, emphasizing its potential to mitigate greenhouse gas emissions compared to virgin fiber production. rPET granules

Advancing Towards a Circular Economy This innovation not only marks a technological breakthrough but also propels the plastics industry towards a circular economy. Enabling endless recycling of PET without quality loss, Itelyum and Plasta Rei set new benchmarks for sustainability and resource efficiency, showcasing the power of collaboration and innovation in fostering a more sustainable future.

Amid global concerns about plastic waste and environmental harm, Itelyum and Plasta Rei offer hope by transforming food packaging waste into high-quality, endlessly recyclable rPET granules. Their success demonstrates the promise of chemical recycling and sustainable practices, marking a significant milestone in the journey towards a circular plastics economy, where plastic waste becomes a valuable resource rather than a pollutant. rPET granules

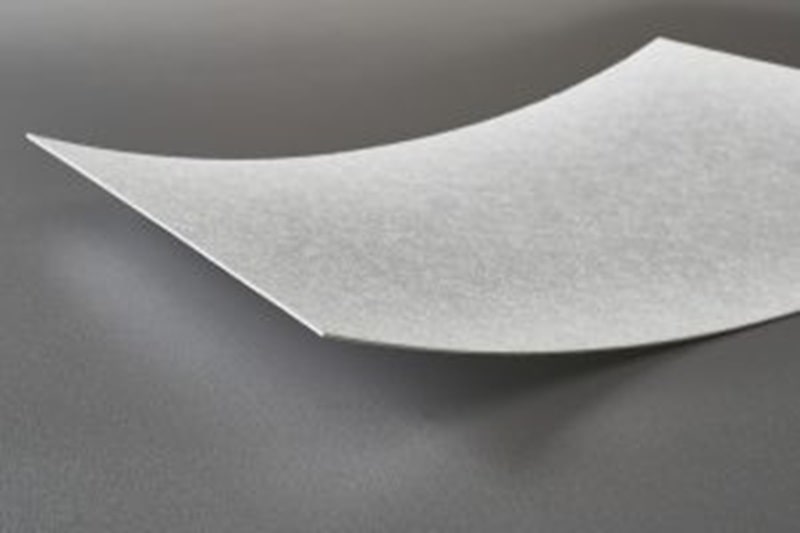

Freudenberg, a leading manufacturer of high-performance materials, introduces a new line of 100% synthetic wetlaid nonwovens made in Germany

These materials, incorporating various polymer-based fibers including ultra-fine micro-fibers, are tailored for filtration and industrial applications. They complement Freudenberg’s existing wetlaid capabilities.

The fully synthetic wetlaid nonwovens are ideal for liquid and air filtration, including support for reverse osmosis membranes, nanofibers, PTFE membranes, and oil filtration. They find use in construction, composites, and other industries. rPET granules

Marketeted under the Filtura® brand, these materials offer versatility and flexibility. They can be composed of polyester, polyolefin, polyamide, and polyvinyl alcohol fibers, with weights ranging from 8g/m² to 250g/m² and fiber lengths up to 12mm. Freudenberg’s manufacturing line combines various bonding technologies, ensuring precise weight, thickness, pore size, and porosity.

Freudenberg’s wetlaid capabilities extend beyond synthetics, incorporating glass fibers, viscose, and cellulose.

Applications range from surfacing veils in glass-fiber reinforced plastics to battery separators, acoustics, and apparel substrates. rPET granules

Freudenberg’s innovative wetlaid nonwovens cater to diverse filtration and industrial needs, offering reliability and performance across a wide spectrum of applications.

Amut: The World’s One-of-a-Kind Recycling Trio

AMUT, a pioneer in recycling technology, has achieved a remarkable feat in Australia with its involvement in three groundbreaking projects: Duet, Choir, and Symphony under the Circular Plastics Australia initiative. This trio of projects marks a unique achievement globally, showcasing AMUT’s expertise in advanced recycling technologies.

The collaboration between AMUT and Circular Plastics Australia, comprising Pact Group, Cleanaway Waste Management, Asahi Beverages, and Coca-Cola Europacific Partners (CCEP), resulted in the establishment of state-of-the-art recycling plants in Albury and Melbourne. These plants aim to recycle approximately 60,000 tonnes of post-consumer plastic packaging annually, converting them into high-quality resins suitable for various applications, including food packaging. rPET granules

Duet and Symphony focus on sorting and washing PET bottles, while Choir targets HDPE and PP materials. The success of these projects is evident, with Duet exceeding its initial output expectations within a year of operation.

Symphony, inaugurated in the presence of government officials, including Federal Environment Minister Tanya Plibersek and Victorian Minister for Environment Steve Dimopoulos, is the largest plastic recycling facility in Victoria. With cutting-edge equipment, Symphony can process up to 20,000 tonnes of recycled PET resin annually, contributing significantly to the circular economy by converting PET bottles into high-value food-grade pellets.

AMUT’s washing lines ensure the purity of recycled flakes while minimizing operational costs and environmental impact, aligning with the global push towards circularity and climate change mitigation. rPET granules

This success further solidifies AMUT’s position as a leader in recycling technology, garnering recognition and trust from customers worldwide.

Avient Corporation, a leading provider of specialized sustainable materials solutions, is thrilled to announce an expansion of its Gravi-Tech REC Recycled Formulations lineup

This new grade incorporates up to 60% ocean-bound plastic waste, alongside recycled fillers, resulting in a remarkable 98% recycled content. Specifically engineered for luxury packaging caps and closures, this innovative material offers enhanced design flexibility and more efficient processing compared to traditional metal options.

Introduced in early 2023, Avient’s Gravi-Tech REC recycled formulations provide density-modified engineered polymer materials with recycled content, offering a sustainable alternative to prime or virgin polymers. rPET granules

This new grade, Gravi-Tech REC GT5200-5089 C I natural, utilizes up to 60% Social Plastic polymer resin material sourced from Plastic Bank, significantly reducing the Product Carbon Footprint (PCF) by over 70% compared to virgin material.

Matt Mitchell, Director of Global Marketing at Avient, emphasized the dual impact of this advancement: not only does it drive material innovation, but it also contributes to social good by addressing plastic waste while supporting vulnerable communities through Plastic Bank’s initiatives.

Gravi-Tech REC formulations boast diverse visual effects suitable for luxury packaging applications like cosmetic and perfume caps, spirit bottle caps, and luxury boxes. Manufactured in Europe, the new Gravi-Tech REC GT5200-5089 C grade is commercially available, with additional food contact-compliant options within the broader Gravi-Tech REC portfolio. rPET granules

Avient’s commitment to environmental sustainability and positive social impact is evident through its integration of recycled materials and ongoing pursuit of sustainable alternatives, showcasing a dedication to advancing both industry standards and global responsibility.

Rice University researchers and collaborators have devised an innovative method to address the challenge of managing glass fiber-reinforced plastic (GFRP) waste

GFRP, widely used in applications like windmill blades and aircraft parts, poses disposal difficulties due to its durability. Traditional disposal methods, such as incineration or solvolysis, are inefficient and environmentally harmful.

To tackle this issue, the team developed an energy-efficient upcycling process. By grinding GFRP into a mixture of plastic and carbon and subjecting it to high voltage, they transformed it into silicon carbide, a valuable semiconductor material. This process, known as flash Joule heating, involves heating the mixture to temperatures between 1,600-2,900 degrees Celsius. rPET granules

The upcycling method not only converts GFRP waste into useful silicon carbide but also offers economic and environmental advantages over conventional disposal techniques. It eliminates the need for resource-intensive methods like incineration and minimizes toxic gas emissions.

The resulting silicon carbide can be utilized in various applications, including battery anodes, due to its superior performance characteristics. The proof-of-concept tests conducted by the research team have shown promising results, paving the way for wider adoption of this upcycling approach. rPET granules

By transforming GFRP waste into a valuable resource, this method supports the principles of a circular economy. It demonstrates the potential to repurpose waste from diverse applications into new, beneficial products, contributing to sustainability efforts and resource conservation.

In 2022, there was a reduction of 19 kilograms per person in municipal waste

In 2022, the European Union saw a reduction in municipal waste production, with each person generating an average of 513 kg, marking a decrease of 19 kg or 4% compared to the previous year’s figure of 532 kg. However, this remained 46 kg higher than the levels recorded in 1995, which stood at 467 kg per person.

There were significant disparities in municipal waste generation across EU member states. Citizens of Austria (827 kg per person), Denmark (787 kg), and Luxembourg (720 kg) produced the highest amounts, while Romania (301 kg), Poland (364 kg), and Estonia (373 kg) had the lowest figures. rPET granules

These variations reflect diverse consumption patterns, economic conditions, and waste management practices across countries. Differences exist in how nations handle waste from households, commerce, trade, and administration.

Regarding recycling, the EU’s average stood at 249 kg per person in 2022, down from 264 kg per person in 2021. Austria (516 kg), Denmark (411 kg), and Germany (409 kg) were the top performers in terms of recycled waste per person, while Romania (36 kg), Malta (75 kg), and Greece (90 kg) recorded the lowest amounts.

Data Source: Eurostat

rPET granules