Plastic Recycling automotive will it be only chinese? 30-06-2023 - Arhive

Plastic Recycling automotive

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Avantium N.V., a prominent provider of renewable chemistry technology, has been acknowledged by the Association of Plastic Recyclers (APR) with Critical Guidance Recognition

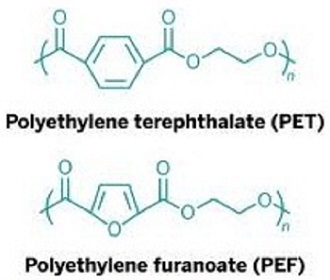

The APR Critical Guidance Protocol is widely recognized as a comprehensive evaluation method for determining the recyclability of plastic packaging designs. Avantium earned this recognition for their utilization of PEF, a bioplastic material produced through Avantium’s YXY Technology, in a multilayer PET bottle.

Avantium has developed the YXY Technology to create FDCA (furandicarboxylic acid), a fundamental component of PEF, which is a 100% plant-based and recyclable plastic. PEF offers an optimal blend of sustainability and performance features, making it suitable for various applications such as bottles, packaging, and textiles.

Currently, Avantium is in the process of constructing the world’s first commercial FDCA facility in Delfzijl, the Netherlands, which is anticipated to be operational by 2024. This milestone will enable the commercial launch of PEF in the market. PEF can be used in fully plant-based monolayer PEF bottles and also provides advantages when combined with PET. For instance, PEF can serve as a barrier material in multilayer PET bottles when a single layer of PET cannot guarantee the necessary shelf life. Unlike nylon, which is commonly used as a barrier in multilayer PET bottles and poses recycling challenges, PEF possesses excellent barrier properties and closely resembles PET, making it a favorable alternative that has minimal impact on the recycling process. Plastic Recycling automotive

To undergo APR Critical Guidance testing in the United States, multilayer PET/PEF bottles containing 7 wt% and 10 wt% of PEF were evaluated by a third-party entity (Plastics Forming Enterprises LLC) and subsequently reviewed by an independent committee appointed according to the APR Recognition Operating Procedures.

Avantium demonstrated that these multilayer PET/PEF bottles are compatible with standard PET recycling practices without compromising the physical properties of the recycled PET. The conclusion was reached that both variations of multilayer PET/PEF bottles meet or exceed the most rigorous test conditions and the strictest APR Critical Guidance criteria.Plastic Recycling automotive

For more information, please visit Avantium’s website.

-Rondo Energy and Siam Cement Group Plan 90GWh Battery Factory, World’s Largest

Planned capacity will produce Rondo Heat Batteries saving 12 million tons of CO2 annually, powering deep decarbonization in the world’s most energy and emissions-intensive industries with economical and highly effective technology.

Siam Cement Group (“SCG”) and Rondo Energy, Inc. (“Rondo”) today announced plans to expand the production capacity of Rondo Heat Battery storage at SCG’s facility to 90 GWh per year, larger than any current battery manufacturing facility worldwide.

Mass production is now underway with a capacity of 2.4 GWh per year already online today. Plastic Recycling automotive

The 90 GWh of planned capacity will result in 12 million tons of CO2 savings annually, equivalent to removing over 4 million ICE vehicles to the road each year.

“Energy storage is just starting to scale around the world,” said Pavel Molchanov, energy analyst at Raymond James. “The size of the addressable market is such that all possible solutions are needed: it is truly an all-of-the-above story. In this context, electric thermal energy storage can play a useful role in addressing the needs of the industrial sector, which has been slow to decarbonize. Plastic Recycling automotive

And, from an energy security standpoint, it is worth noting that this technology avoids the use of scarce and expensive materials.”

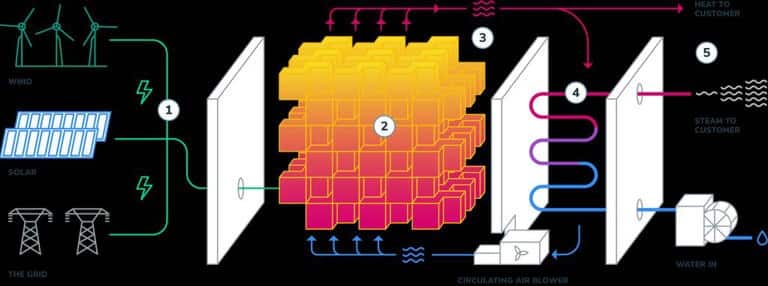

Refractory brick has been used for centuries for industrial heat storage, and is made of Earth’s most abundant elements: oxygen, silicon, and aluminum. Rondo’s breakthrough Heat Battery stores electric power as high temperature heat in refractory brick, without the use of combustibles, critical minerals, toxics, or liquids.

With Rondo’s technology, wind and solar can deliver continuous zero-carbon industrial heat at lower cost than fossil fuels, a critical need for industries worldwide producing every commodity from steel to baby food. The first Rondo Heat Battery is now commercially operating at a California ethanol plant, serving an industrial customer with the world’s highest temperature, highest efficiency energy storage of any kind.

SCG, through its subsidiary SRIC, produces refractory brick at world-class quality and scale. Rondo and SCG are together addressing the next step toward large-scale industrial decarbonization: Heat Battery production at large scale, with the highest quality, long-term durability, and certainty of delivery. Rondo and SCG have brought together their innovations and capabilities to establish the multi-GWh production now underway. That production experience is the foundation for the planned expansion announced today.

SCG’s world class refractory production operations are the largest in Southeast Asia. SCG’s manufacturing excellence has been recognized by prestigious global quality awards including the Deming Prize for total quality management and supply refractory for leading industries in over 80 countries. Plastic Recycling automotive

“Rondo offers an innovative solution to reduce the carbon emissions from industrial process heat used in factories worldwide. SCG can use Rondo’s technology to lower our own carbon emissions, and SCG Cleanergy can partner with Rondo to help our customers cut emissions,” said SCG’s Executive Vice President, Thammasak Sethaudom. “We also realized that we can leverage our 70 years of technical expertise in the refractory business and supply chain to support Rondo’s mission to decarbonize industrial process heat, and we are happy to increase our capacity to meet market demand.”

“SCG has been a phenomenal partner,” said Rondo CEO John O’Donnell. “We found we had a common vision and uniquely complementary capabilities to bring this technology to world scale to address the greatest challenge of our times. With the technology now in commercial operation, Rondo’s next milestone is creating the delivery capacity to meet the growing needs of projects worldwide.” Plastic Recycling automotive

Industry uses more energy than any other part of the world economy, and most industrial energy is used as heat. Industrial heat consumes a quarter of total world energy and today releases a quarter of the world’s CO2. Industrial heat has been seen as “difficult to decarbonize” due to challenges of cost, continuity, and temperature. Rondo Heat Batteries transform intermittent wind and solar power into the continuous high-temperature and low-cost heat that industry needs. This planned production will support installations powering a wide range of industries, from mining and metals to fuels to food production, at facilities around the world.

Rondo is an award-winning innovator in energy storage, having been selected by DoE among others for its leadership and transformation of lower costs of energy storage with its heat battery technology. Plastic Recycling automotive

“Over the last few years we’ve seen validation of our founding vision,” said O’Donnell, “Decarbonizing industrial heat is a trillion-dollar market requiring far more storage than the electric grid. The technology is here now. The demand is here now. This planned expansion means that the capacity is here now as well. Working with SCG, Rondo will maintain and extend our leadership position, and serve our customers’ rapidly growing demands with world-class quality and certainty of supply.”

Credit : Rondo Energy and Siam Cement Group

-Lummus Technology and MOL Group Establish Partnership for Advanced Waste Plastic Recycling

Underscores Lummus and MOL’s commitment to developing sustainable solutions for the circular economy

Lummus Technology, a global provider of process technologies and value-driven energy solutions, and MOL Group, the leading integrated Central Eastern European oil and gas corporation, have announced their agreement to cooperate in the deployment and integration of chemical recycling of plastics at MOL’s assets in Hungary and Slovakia. Chemical recycling of plastics is part of MOL’s commitment to collect close to 5 million tonnes of municipal solid waste, which includes the treatment and related investments.

“MOL Group and Lummus have a long track record of successful collaboration in various technology areas, and we are proud to now partner with MOL again to address a critical challenge for our industry and society,” said Leon de Bruyn, President and CEO of Lummus Technology. “Both organizations are playing a leadership role in the circular economy, and by joining hands we will help further develop and deploy sustainable solutions to recycle plastic waste.” Plastic Recycling automotive

MOL has committed to drive circularity and has recently invested in addressing waste plastics recycling in Central Europe. With a total annual capacity of 40,000 tons, MOL can offer a wide range of sustainable compounds for various industries, including the automotive, construction, building and packaging sectors. The company’s aim is to build a production portfolio of more than 100,000 tons of recycled plastic materials.

“We’re thrilled to extend our cooperation with Lummus in a field that largely contributes to our strategic goals in reaching net zero by 2050,” said Gabriel Szabó, Executive Vice President of MOL Group Downstream. “MOL Group is actively building a strong plastic recycling and waste integration portfolio as we are aware of its crucial role in the circular economy, and sustainable business models require such mindset that considers everything as raw material and potential energy source. The waste plastic pyrolysis technology, and Lummus’ expertise will help us to optimize our value chain, and make our business more sustainable.”

Lummus’ Green Circle business unit will provide to MOL its advanced waste plastic pyrolysis technology, which effectively converts plastic waste into high-value chemicals and feedstocks, creating circularity. This technology is a proven, reliable, economically attractive solution to address the global plastic waste problem, which offers additional environmental benefits such as a lower carbon footprint and the elimination of char production. Lummus will also provide its experience and expertise in steam cracking, catalytic cracking and residue processing technology to ensure that integration with MOL’s existing assets is optimized. Plastic Recycling automotive

-China is the new automotive superpower

The target will be reached this year together with the confirmation of world leadership: 24.9 million vehicles in ’23 (and up to 29.1 million in ’27), ie +4% per annum.

Therefore, 1923 will be the year of records for Beijing and its brands. China, in fact, will also become the first world exporter of cars (overtaking Japan), with a growth rate of 80% over the first quarter of ’22.

All data pitted by AlixPartners, a leading global consultancy firm, and contained in the 20th «Global automotive outlook». «For the first time – commented Dario Duse, Emea co-leader of the Automotive & Industrial team as well as country manager of AlixPartners for Italy – more than 50% of the local market will be satisfied with vehicles produced by domestic brands (35% in 2020); and they will also contribute to the growth of exports, but with still limited effects in Europe, where a share gain from 4% to 6% is expected in 2026».

It means that Europe, before being subjected to the dreaded invasion of Chinese cars (the tariffs remain unknown), will have a few years to prepare a defense plan, but above all a counterattack.

«Technology control, government support, cost competitiveness and business models that respond better and faster to market demands are the basis of China’s success. Traditional players, at this point, will have to be ready to review their approach to compete on the Beijing market and defend their shares in the West», reflected Duse.

In fact, the Chinese car industry, known for clumsily copying European models, has learned and been able to apply Italian methods and technologies in the best possible way.

In terms of style and interiors, the top three favorite brands of the Beijing public are 100% local: Xpeng, Byd and Zeekr. Plastic Recycling automotive

More generally, meanwhile, the estimate of investments for the electric transition has increased from 526 billion dollars (2022-2026) to 616 billion (2023-2027). The increase of 90 billion, explains AlixPartners, is mainly due to the batteries. Furthermore, according to the study, European self-sufficiency for the production of batteries could arrive in 2026. In this sense, the agreement signed by Minister Adolfo Urso with colleagues from France and Germany is important in order to establish together extraction objectives , processing and recycling for raw materials (cost increased by 87% from 2020).

The markets: the world is returning to pre-Covid (83 million the estimate for 2023, +5%), in the USA +10% and in Europe +6%.

AlixPartners are optimistic about electrification: in 2035 the expectation is that battery-powered vehicles will represent the majority of global volumes: 59% in the US, 82% in Europe and 66% in China. Plastic Recycling automotive

And while Ford cuts 1,000 jobs in the US for investments in electricity, there is talk of Dieselgate again: in Germany, the former CEO of Audi, Rupert Stadler, was sentenced to 1 year and 9 months for fraud, but with the conditional, and a fine of 1.1 million.

-Kent, a Dubai-based energy and chemicals engineering company, has secured the front-end engineering design (FEED) contract for ExxonMobil’s plastic recycling initiative

The contract encompasses potential expansions at seven facilities across the globe.

Kent has been appointed as the FEED contractor for the prospective expansion of ExxonMobil’s advanced recycling facilities. The company will provide FEED services for the assessment of ExxonMobil’s advanced recycling facilities in various locations, including Baytown and Beaumont in Texas, Baton Rouge in Louisiana, Joliet in Illinois, Sarnia in Ontario, Rotterdam in the Netherlands, and Antwerp in Belgium. Notably, Kent successfully designed and implemented a trial unit in Baytown between 2021 and 2022. This unit began commercial operations in December 2022 and stands as one of the largest advanced recycling facilities in North America. Plastic Recycling automotive

Tush Doshi, the Chief Operating Officer of Kent, expresses pride in their association with the project and emphasizes the remarkable work they have been undertaking in the recycling waste sector. Doshi considers this contract win a significant milestone and believes the program will showcase the evolving efficiency of the recycling process, ultimately leading to a better future for the planet.

ExxonMobil’s recycling technology plays a crucial role in diverting hard-to-recycle plastic scrap from landfills or incineration, enabling the production of raw materials for new plastic and other valuable products.

This approach aligns with customer goals for achieving a circular economy. Sean McNelis, the ExxonMobil venture project manager, highlights the importance of advancing this portfolio of projects into the FEED phase as a means to expand advanced recycling on a global scale and contribute to a more circular economy. Plastic Recycling automotive

-Cutting-edge batteries that harness the power of quantum physics, known as quantum batteries, are revolutionizing energy storage

These devices offer remarkable efficiency and lightning-fast charging capabilities, surpassing the limitations of traditional batteries.

A visionary study led by Marco Polini from the University of Pisa has brought this concept to life, with the support of a 2.7 million euro loan for the pioneering startup, Planckian.

Quantum mechanics, governing the behavior of subatomic particles, presents extraordinary phenomena with potential groundbreaking technological applications, such as cryptography, quantum computers, and now, quantum batteries.

Building upon an initial idea in 2018, the team at the University of Pisa has established Planckian, dedicated to developing energy storage technologies that capitalize on the unique principles of quantum mechanics. Plastic Recycling automotive

Marco Polini, co-founder of the startup alongside Vittorio Giovannetti, states that Planckian is the first and only initiative to leverage this knowledge for advancing energy management technologies.

Excitingly, this venture has garnered significant attention from investors, securing a substantial 2.7 million euros in an investment round led by “Eureka! Fund I – Technology Transfer,” managed by EUREKA! Venture SGR. Plastic Recycling automotive

Tech4Planet, managed by CDP Venture Capital SGR, and Exor Ventures, along with notable business angels, have also joined in supporting this promising endeavor.

-Krones: First aseptic line for Coca-Cola in India

For 60 years now, Kandhari Beverages has been bottling the complete range of Coca-Cola products in India – with a workforce that now totals more than 400 people at five locations. Of those, they’ve been working with Krones for the past 30 years. “Our partnership with Krones is very strong,” says Anil Kumar Sharma, supply chain director for Kandhari Beverages. The company already has eight Krones lines up and running. Soon the ninth will go into operation. And for the first time, it will be an aseptic line. It’s new ground not only for Kandhari Beverages but for all of India: It will be Coca-Cola’s very first aseptic line in the country. Plastic Recycling automotive

The Coca-Cola bottler has been an innovator since the very beginning. “In 1997, for instance, we were the first bottler in the country to use PET bottles,” says Anil Kumar Sharma, supply chain director for Kandhari Beverages. Krones delivered the line that made it possible, and that same equipment continues to operate reliably today. In the intervening years, a loyal, trusting relationship has developed between the two companies ¬– and Krones remains Kandhari Beverages’ top-choice technology supplier. That held true when it came time to order a line for cold aseptic filling of sensitive beverages into sterilized containers. In this process, the product is heated only very briefly, thus ensuring minimal-to-no impact on quality and taste. Plastic Recycling automotive