This content has been archived. It may no longer be relevant

“The right choice for your production”

Plastic loop

Bright-PET chips – EXCLUSIVE-Eni exploring sale of stake in bioplastic maker Novamont

More…

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

These Chinese LFP batteries boast ultrafast charging

In a groundbreaking development, Zeekr, a brand under the Geely group, has unveiled a cutting-edge lithium-iron-phosphate (LFP) battery during the Zeekr Power Day event. Known as the Golden Brick Battery, this innovation promises an astonishing 500 km of autonomy in just 15 minutes, leveraging an 800 Volt architecture. Presented as a game-changer in the field of LFP batteries, known for their cost-effectiveness and ease of production compared to NMC lithium-ion counterparts, the Golden Brick Battery is set to hit the market in 2027, featuring an unprecedented 80% plus active material percentage.

What sets the Golden Brick apart is its remarkable resilience – proven to function flawlessly after enduring extreme conditions, including an 8-hour exposure to -45 degrees and exposure to flames at 1,000 degrees. Plastic loop

This remarkable achievement was showcased during Zeekr Power Day, where the company illustrated its progress and future plans.

Notably, Svolt, a Chinese company under Great Wall ownership, also announced a revolutionary product during its Battery Day event. The Svolt Short Blade, featuring LFP chemistry and an 800 Volt architecture, can achieve a rapid 5C charging speed, translating to a remarkable 350 km of autonomy in just 10 minutes. Excitingly, the Short Blade is expected to hit the market in 2024, further advancing the landscape of fast-charging LFP batteries. Plastic loop

From Japan, a system for producing cheaper batteries

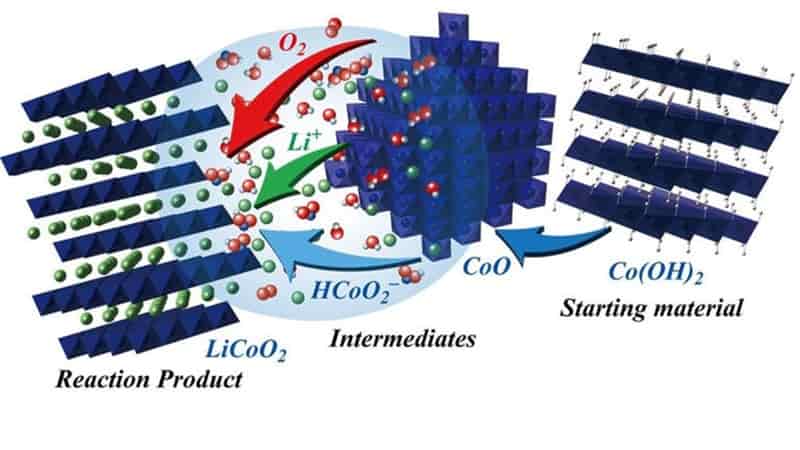

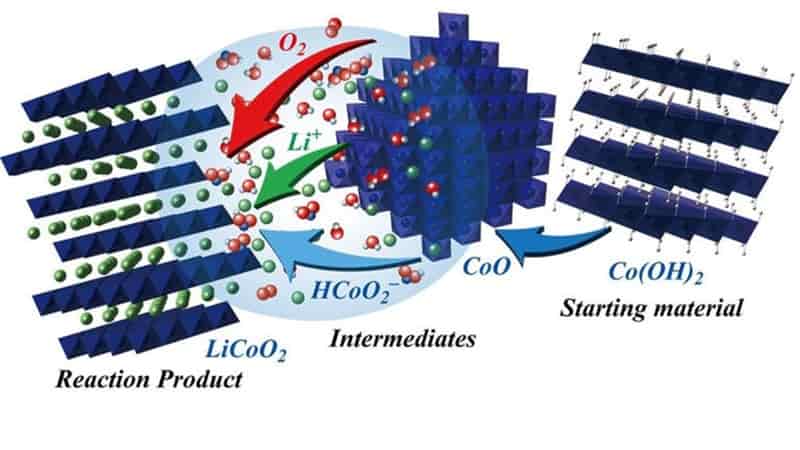

A breakthrough in battery technology has emerged from Japan, promising to revolutionize the production of lithium cobalt oxide, a crucial component in lithium-ion batteries. Researchers from Hokkaido University and Kobe University have developed a groundbreaking method that synthesizes lithium cobalt oxide at a significantly lower temperature of 300 degrees Celsius, in contrast to the current 800 degrees Celsius requirement, and achieves a remarkable tenfold increase in speed.

Traditionally, manufacturing lithium cobalt oxide involves lengthy industrial processes spanning 10 to 20 hours, necessitating exposure to high temperatures.

The Japanese researchers, however, have streamlined the process to a mere 30 minutes at a lower temperature, resulting in substantial time and energy savings.

The innovative approach employs cobalt hydroxide and lithium hydroxide as base materials, with sodium and potassium hydroxide as additives. Through systematic experimentation, the team perfected a hydroflow process for synthesizing layered crystals of lithium cobalt oxide. Plastic loop

While the newly produced compound exhibits slightly lower technical characteristics and electrochemical properties compared to its high-temperature counterpart, it still delivers comparable performance.

Professor Masaki Matsui, leading the research project, highlighted the crucial role of water molecules in enhancing the crystallinity of the final product, underscoring a deep understanding of the chemical reactions driving the production process.

This groundbreaking method holds promise for accelerating battery production at reduced costs, contributing to the widespread adoption of electric vehicles and fostering a more sustainable future. Plastic loop

Closing the plastic loop

Plastic products bring important benefits to society – they help improve living standards and deliver health, safety and sustainability benefits. Plastic waste, however, is a global issue and where waste is not managed appropriately, it ends up polluting the environment. Estimates suggest that of the 353 million tonnes of plastic waste generated globally, only 9% is recycled, and the remainder goes to landfill or incineration – or is unmanaged after use.

Shell, alongside many others, is committed to finding lasting solutions to plastic waste. We want to play our part in the transformation of the plastics value chain from linear to circular, reducing the need for raw materials and introducing more recycled products into everyday life. Plastic loop

Chemical recycling: key to tackling plastic waste

In recent decades, plastic recycling has mostly been limited to plastic waste streams which are relatively easy to collect and mechanically recycle like drink bottles or milk containers. However, alternative techniques are needed for plastics that cannot be mechanically recycled and are currently incinerated or go to landfill. These are hard to recycle plastics like snack bags, plastic film, garden furniture and others.

Chemical or advanced recycling uses different technologies to expand the types of plastics that can be recycled. Shell is working on several technologies to utilise waste and is focusing particularly on chemical recycling through pyrolysis: a special heating process that turns hard-to-recycle plastics into a liquid. Plastic loop

This liquid, referred to as pyrolysis oil, replaces virgin hydrocarbons in the production of chemicals which are the building blocks of a wide range of products we use every day, including new plastic products.

More…

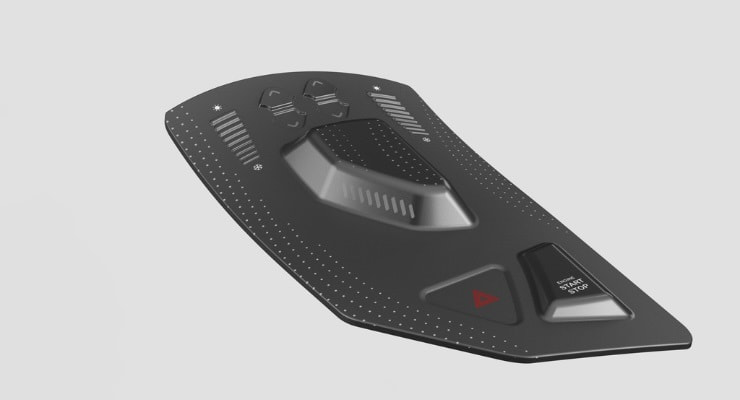

Eurecat Develops New Ultra-Thin Smart Interface for New Generation of Cars

The technology center presents the Púlsar project, which has developed a smart plastic surface just 3 millimeters thick.

The Eurecat technology center has developed a smart plastic surface just 3 millimeters thick, which has an interface that allows users to communicate with a machine, software or intuitive system with built-in LED lighting and capacitive sensors which is expected to be embedded in the central electronic system of the new generation of cars.

“The need for digital transformation and the growing importance of design, integration, personalisation and standing out from the competition means the industry is constantly evolving and developing highly innovative products and services,” says David Pardos, head of business development in Eurecat’s Mobility team. Plastic loop

“By way of example, functional surfaces with haptic response activation featuring tactile sensations are gaining ground.”

The innovation has been created as part of the Púlsar project which has been run at Eurecat’s plastronics pilot plant. The facility specializes in functional printing and embedded devices and “has a track record spanning over 10 years of experience in electronics whether printed, hybrid or injected in plastic parts and functional fabrics,” notes Cristina Casellas, head of technology transfer at Eurecat. “This enables the technology centre to deliver solutions to complex and specific challenges across a wide range of sectors such as the automotive industry.” Plastic loop

The Púlsar project can be seen at the Automotive Interiors fair in Stuttgart, Germany, where Eurecat is also showcasing plastic parts which imitate various textures such as marble, wood and fabric along with plastronics parts simulating push buttons with printed contact sensors and embedded optoelectronic devices.

DIN SPEC 91481 improves the quality assurance of polyamide-based recyclates through the correction of previously insufficient data quality. It provides clear guidelines for the classification and description of waste and recyclates, thus simplifying trade in recycled plastics. In addition, the cooperation partners have developed a concept for a digital product passport for recycled plastics and waste along the entire value chain, which can also be implemented at European level. Plastic loop

The digital product passport in accordance with DIN SPEC 91481 ensures comprehensive data collection and processing from raw material to compound. The aim is to ensure the data quality of the material over its entire life cycle, and to create and legally pass on the often-missing information at raw material level.

“Quality variations and price differences between virgin and recycled plastics currently make it difficult to expand the recyclate market. Standards facilitate the use and procurement of recycled plastics. Plastic loop

They are therefore a prerequisite for the scaling of the recycling industry. DIN SPEC 91481 creates more clarity for polyamide-based waste and recyclates and provides an important step towards a deeper digitalisation of the plastics and waste industry,” remarks Christian Schiller, founder and CEO of Cirplus.

More…

Copyright: Cirplu

US import prices fall 0.4%, export prices by 0.9% in Nov 2023

The price index for imported fuel declined by 5.6 per cent in November following a 3.7-per cent drop in October. The November decrease was the largest monthly decline since the index fell by 5.6 per cent in February this year.

Prices for non-fuel imports in the United States rose by 0.2 per cent in the month, after declining by 0.2 per cent in each of the three previous months. The November increase was the first one-month advance since a 0.4-per cent rise in February 2023.

Despite the November increase, non-fuel import prices declined by 0.4 per cent over the past year. Plastic loop

The price index for non-fuel industrial supplies and materials rose by 0.2 per cent in November following a 0.6-per cent decline the previous month.

Prices for major finished goods import categories remained mostly unchanged in November.

Lower prices for non-agricultural exports in November more than offset higher agricultural prices.

Non-agricultural export prices decreased by 1 per cent for the second consecutive month in November. The declines followed a 2.7-per cent increase for the third quarter this year, a BLS release said. Plastic loop

The price index for non-agricultural industrial supplies and materials fell by 2.2 per cent in November, after decreasing by 2.4 per cent the previous month. Lower fuel prices drove the declines for both months, decreasing by 5.1 per cent in November and by 4.3 per cent in October.

More…

Plastic tax – The APR Design® for Plastics Recyclability Program, formerly known as Meets Preferred Guidance (MPG), is undergoing a notable expansion, introducing six additional packaging components 16-12-2023

Plastic loop