PET Recycling – Alfa, the Mexican conglomerate, plans to spin off its polyester subsidiary Alpek, one of the leading producers in the U.S., to focus more on its core food business 25-10-2024

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Avantium Celebrates the Official Opening of its FDCA Flagship Plant

Avantium N.V., a leading company in renewable and circular polymers, today celebrated the Official Opening Ceremony of its FDCA Flagship Plant in Delfzijl, the Netherlands. The plant opening was officiated by Her Majesty Queen Máxima of the Netherlands, in the presence of (intern)national and local dignitaries, partners and Avantium employees.

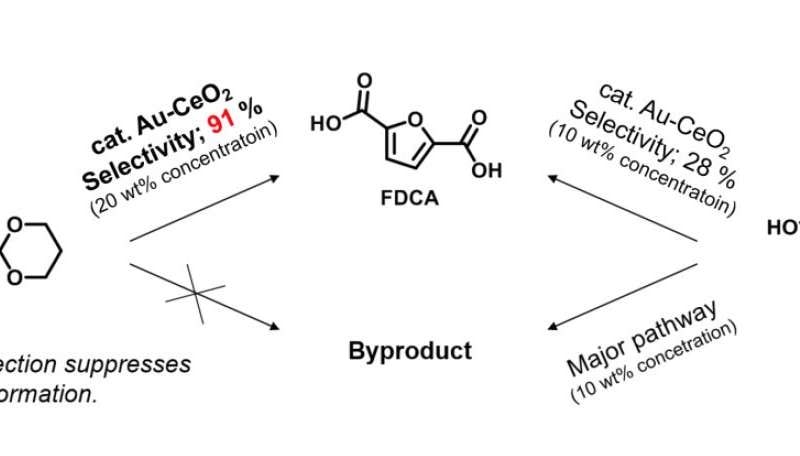

The official opening of Avantium’s FDCA Flagship by Her Majesty Queen Máxima marks a significant milestone for Avantium, commemorating the start of something extraordinary and highlighting Avantium’s progress in developing renewable, circular materials and celebrating the dedication and hard work of its committed employees and partners. In the world’s first commercial plant, Avantium will produce 5 kilotons of FDCA (furandicarboxylic acid), the essential building block for 100% plant-based and circular plastic PEF (polyethylene furanoate), known under the brand name Releaf. Avantium’s Releaf is a revolutionary material set to transform the plastics industry, with versatile applications including bottles, packaging, films, and textiles.

Avantium CEO Tom van Aken comments: “Today marks the dawn of a new era for Avantium and the future of sustainable plastics. Our new FDCA plant embodies our commitment to innovation and sustainability. We are excited to lead the way in producing Releaf, a material that offers a viable alternative to traditional petroleum-based plastics. This plant is not just a testament to our technological advancements but also to our dedication to creating long-term, sustainable value for all our stakeholders. We will now commence the start-up of the FDCA Flagship Plant, introduce Releaf products to the market, and expedite the rollout of our FDCA/PEF licensing strategy.”

“Cutting-edge Solution for recycling multi-layer packaging: Unveiling a myth-busting Technology”

Multilayer packaging is good for mankind as it preserves and protects the content. MLP is the mainstay of the FMCG industry, combining functionalities of dissimilar materials, such as excellent barrier against water, vapor and gases like oxygen, carbon dioxide, along with good mechanical and ability to withstand low-temperature environments. Thereby, increasing the shelf life of the product considerably and potentially helps in significantly reducing the carbon footprint throughout the food supply chain. PET Recycling

However, due to lack of efficient collection and processing or safe disposal system, MLP poses several challenges. In India, the system of primary waste collection is practically non-existent. Door-to-door collection of wastes from household, shops and establishments is insignificant and unorganized. As a result, most of the waste MLP is difficult to collect and dispose in a proper manner to reduce adverse impact on environmental and public health. Moreover, it is widely believed by various stakeholders that the MLP waste being generated is “non-recyclable” because the polymers involved in different layers have different rheology points. PET Recycling

As of today however, the technology does exist to recycle MLP that renders Multi-layer packaging recyclable in spite of the fact that multilayered polymers have different functionalities and together act to provide the durability that MLP’s offer.

EBC 24 – The European Bioplastics Conference 2024

We are happy to announce that the EBC 24 will take place on 10/11 December 2024 at the Titanic Hotel Berlin, Germany.

The European Bioplastics Conference is Europe’s leading business and discussion forum within the global bioplastics sector. More and more brands and manufacturers are embracing the potential of biopolymers, and policy makers are increasingly streamlining their efforts to create frameworks that benefit the growth of sustainable bio-industries. Now is the time to put bioplastics at the top of the agenda of a biobased circular economy in Europe and beyond. PET Recycling

The registration for the EBC 24 is now open and we are excited to welcome you on 10/11 December 2024 in Berlin or online.

Please have a look at our conference programme here.

The hybrid format of this year’s event will again allow you to join either in person at the Titanic Hotel Berlin or comfortably log-in from your home base. Both of which offer unique networking opportunities.

Of course, we will also have an excellent exhibition on- and offline. Just choose the right type of booth to give your company visibility at the conference. PET Recycling

This year we are also offering different kinds of sponsorship options, so that you can engage even more with our event.

Alfa, the Mexican conglomerate, plans to spin off its polyester subsidiary Alpek, one of the leading producers in the U.S., to focus more on its core food business

The decision will be finalized during an extraordinary shareholders’ meeting on October 24. If approved, a new entity named Controladora Alpek will be created and listed on the stock exchange in 2024. Alfa shareholders will receive one share of Controladora Alpek for each Alfa share they own, while still holding their Alfa shares. PET Recycling

Alpek, headquartered in Mexico, produces both virgin and recycled PTA and PET, along with polypropylene via its Indelpro joint venture with LyondellBasell. The company also manufactures expanded polystyrene (EPS) under the brand Styropek. Alpek operates about 30 facilities and has an annual polyester production capacity of approximately 8.6 million tons. In 2023, Alpek generated $7.76 billion in revenue, representing 48% of Alfa’s total sales.

A groundbreaking laser research center at Colorado State University (CSU) aims to advance fusion energy

The ATLAS (Advanced Technology Lasers for Applications and Science) facility, located on CSU’s Foothills campus, will play a key role in pursuing “limitless” energy. It will house an array of high-power lasers, capable of firing nearly 7 petawatts—over 5,000 times the electricity generation capacity of the U.S.—at a fusion target the size of a human hair for just 100 quadrillionths of a second. CSU President Amy Parsons highlighted CSU’s leadership in laser research and sustainability during the facility’s dedication.

ATLAS’s lasers are expected to revolutionize nuclear fusion, but their applications stretch further. PET Recycling

The facility will also enable breakthroughs in medical research, particularly cancer treatment, and innovations in microchip lithography and X-ray imaging of fast-moving objects, such as aircraft turbines. Heike Freund, COO of Marvel Fusion, underscored fusion’s potential to provide clean, virtually limitless energy. The collaboration with Marvel Fusion places CSU at the forefront of fusion and laser research.

Construction begins this month, marking a significant step toward transformative advancements in clean energy and technology, with implications extending well beyond the energy sector. PET Recycling

One petawatt (PW) equals 1,000,000,000,000 kilowatts (kW)

This milestone marks a major advancement in their efforts to accelerate the energy transition and support the circular economy of plastics. Developed through a strategic partnership formed in 2020, Rewind® PET offers an innovative solution for recycling all types of polyethylene terephthalate (PET) waste, including those challenging to recycle mechanically. PET Recycling

Backed by the French Environment and Energy Management Agency (ADEME), the collaboration led to the construction and commissioning of the demonstration unit, which completed a one-year trial program validating the technology’s performance. The process involves depolymerizing PET via glycolysis, followed by purification of the resulting monomer, BHET, which can then be re-polymerized. This approach efficiently removes additives and colorants, producing high-purity recycled PET.

The commercialization of Rewind® PET now enables Axens to offer a comprehensive license package, including process design, performance guarantees, proprietary equipment, and technical support. PET Recycling

The recycled PET, produced using pure BHET, has already received approval from major food packaging and cosmetics companies, highlighting its potential for widespread adoption in various industries.

PET Recycling