Plastics recycling

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

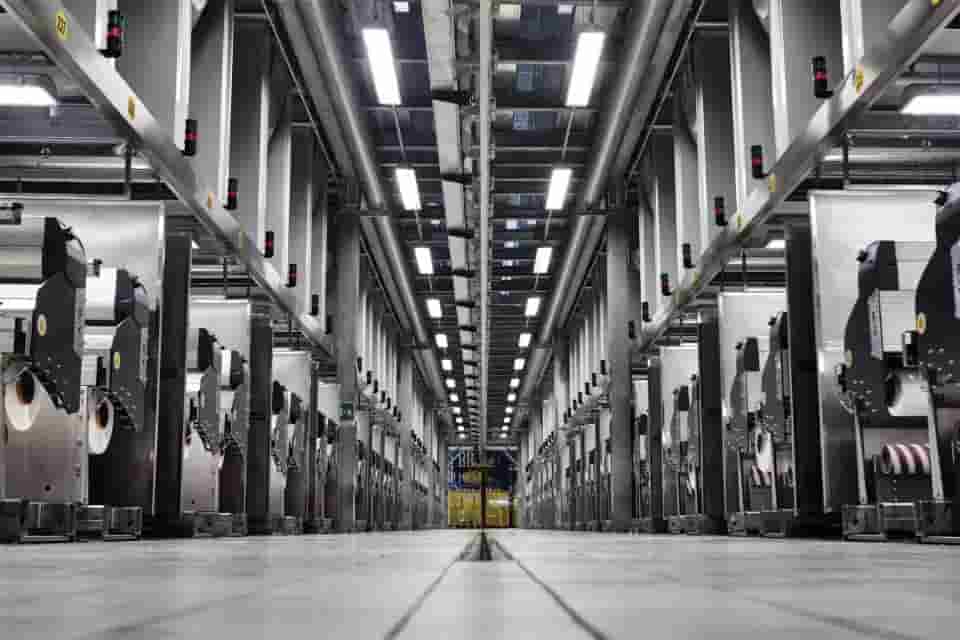

Weaving and knitting machine sales buoyant in 2023

Shipments of new textile machinery increased in most segments in 2023, according to the ITMF’s 46th International Textile Machinery Shipment Statistics just released by the International Textile Manufacturers Federation (ITMF).

The report covers six segments of textile machinery for spinning, draw-texturing, weaving, large circular knitting, flat knitting and finishing. It has been compiled in cooperation with more than 200 textile machinery manufacturers representing a comprehensive measure of world production. Plastics recycling

Spinning

The total number of shipped short-staple spindles increased by 155,000 in 2023 to a level of 9.78 million.

The six largest investors were, in order, China, India, Turkey, Bangladesh, Uzbekistan and Egypt. The 475,000 spindles shipped to Africa represented an increase of +120% and the 81,000 which went to South America a jump of +140% on 2022.

One million open-end rotors were shipped worldwide in 2023, 200,000 less than in 2022, and China, India and Turkey remain the biggest investors. Plastics recycling

Global shipments of long-staple (wool) spindles increased to 98,000 and while 25,000 went to Europe, China remained the biggest investor.

Texturing

Global shipments of single heater draw-texturing spindles, mainly used for polyamide filaments, fell by 33% from nearly 65,000 thousand units in 2022 to 43,000 in 2023. China received 90% of all deliveries.

More…

Coperion, Herbold to jointly present products, solutions at Fakuma

The companies say they will use virtual animation to give show attendees a glimpse of entire plastic processing and recycling systems. Plastics recycling

Recycling equipment and technology vendors Coperion and Herbold Meckesheim, both based in Germany, say they will jointly present numerous product and process solutions for the compounding and recycling of plastics at Fakuma 2024, scheduled for Oct. 15-19 in Friedrichshafen, Germany.

The equipment companies say they will demonstrate their expertise in realizing entire systems using virtual animation. Attendees at the international trade fair for plastics processing will be able to view both a complete compounding plant as well as an entire system for plastics recycling. The companies say the processes involved can be experienced digitally with the aid of simulations, and visitors will be able to look at individual components and their functions. Plastics recycling

Additionally, rotors from Herbold granulators will be on display in various sizes and for a number of applications.

Along with individual components, Coperion and Herbold say they deliver entire systems for plastics recycling. From mechanical processing—shredding, washing, separating, drying and agglomerating of plastics—to bulk material handling, as well as feeding and extrusion and to compounding and pelletizing, the companies say their plants cover the entire plastics reclamation process chain. Plastics recycling

More…

Hyosung Presents New Eco-Friendly Yarns And SS 26 Textile Trends At China International Textile Fabrics And Accessories Expo

With the aim of introducing new sustainable textile solutions and fresh new looks to its entire value chain, Hyosung will exhibit at the China International Textile Fabrics and Accessories (Autumn/Winter) Expo – the world’s largest professional fabric and accessories exhibition – taking place in Shanghai this August 27-29. The Expo comprehensively showcases new products, technologies, trends, and concepts in the textile field, promoting healthy and sustainable industry development through collaboration. Plastics recycling

“This year, we look forward to leading 27 domestic and international partners in participating in the exhibition, forming the Hyosung exhibition group, occupying a large 828 sqm booth to provide the best experience for every visitor,” said Scott Park, Hyosung Marketing Director, China. “Hyosung combines environmental sustainability with technology and market demand, highlighting new yarn technologies to provide a new visual feast.” Plastics recycling

At the Expo, Hyosung will focus on presenting its multi-functional and eco-friendly yarns, including its regen Spandex and regen BIO spandex. Hyosung’s RCS-certified, 100% recycled regen Spandex is made from the reclaimed waste that occurs from Hyosung’s manufacturing process. regen BIO Spandex is made with renewable resources instead of petroleum-based materials, reducing carbon footprint and dependence on non-renewable resources. Hyosung three of bio-based Spandex yarns made with varying amounts of content made from renewable resources: regen BIO, regen BIO+, and regen BIO Max.

Additionally, Hyosung will highlight its popular CREORA® Fresh Spandex, which will now be produced domestically in China. CREORA Fresh Spandex features odor-neutralizing functionality with high elasticity. Plastics recycling

Using a chemical neutralization method, CREORA® Fresh can efficiently and permanently neutralize odor components like ammonia, acetic acid, and isovaleric acid, maintaining freshness and comfort.

More…

Indonesia has canceled its plan to impose an excise tax on plastic products, a proposal initially aimed at curbing the nation’s severe plastic waste issue

First introduced in 2019, the tax was intended to apply to single-use plastic items such as bottles, bags, and packaging. The goal was to reduce plastic consumption and environmental damage by levying a tax of IDR 200 (USD 0.02) per plastic bottle, particularly in the food and beverage industry. Plastics recycling

However, the plan faced significant opposition from industry groups like the Aromatic, Olefin, and Plastic Industry Association (Inaplas). These groups argued that the tax would harm Indonesia’s manufacturing sector, especially companies reliant on plastic packaging. Fajar Budiono, Secretary-General of Inaplas, emphasized that the excise would lower domestic demand for plastic products and could increase imports of untaxed foreign goods. He also noted that plastic is still essential due to its durability and cost-effectiveness, with no affordable alternatives available.

Critics further warned that the tax would disproportionately affect consumers, particularly in regions where tap water is unsafe, leading to higher prices for essential bottled water. Ultimately, concerns about the economic impact on both industries and consumers led to the scrapping of the tax proposal. Plastics recycling

China’s Steel Overproduction: A Global Economic Concern

China, the world’s largest steel producer, is facing a significant crisis due to overproduction. With annual output exceeding a billion tonnes, China accounts for over half of global steel production. However, a sharp decline in domestic demand—driven by a housing market downturn and slowed infrastructure investment—has led to a steel surplus, raising global concerns. Plastics recycling

Impact of China’s Steel Surplus China’s housing market, once a major driver of steel demand, has drastically slowed, leaving the country with excess steel. To mitigate this, Chinese producers are flooding international markets, pushing prices down. This influx poses a severe threat to steel producers worldwide, particularly in the United States, Germany, and Latin America. In these regions, local industries are struggling to compete with cheap Chinese steel, risking plant closures and job losses.

Global Economic Repercussions The effects of China’s steel crisis extend beyond the steel industry, with potential global economic implications. In Europe, where steel demand is already weak, Chinese competition could worsen the economic outlook, particularly in countries like Germany. Plastics recycling

China is attempting to address the crisis by reducing steel production capacity. However, this restructuring is complex and fraught with challenges, as it must balance overcapacity reduction with maintaining domestic economic stability.

The global steel industry now faces significant uncertainty, and the ability of major players like China, the U.S., and Europe to manage this crisis will be crucial for the future of millions of workers and global economic stability. Plastics recycling

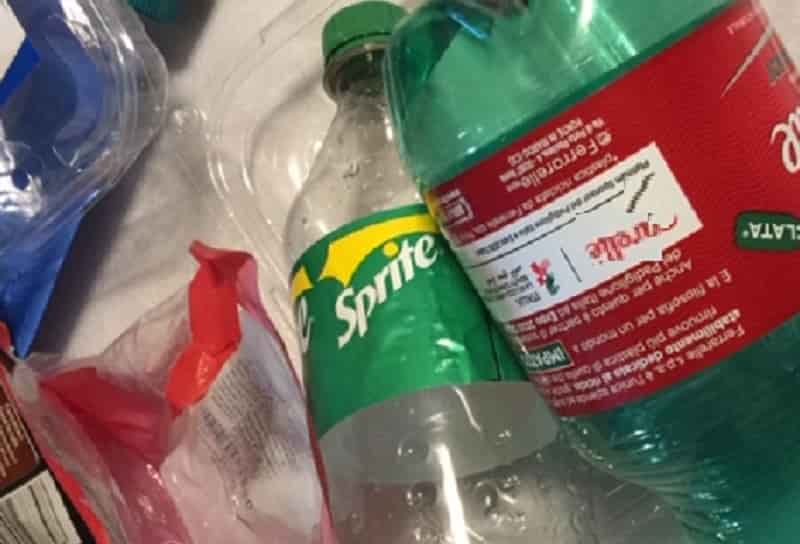

Is recycled plastic safe for food contact? If the company making it says so, according to the FDA

Recycled plastic can be more toxic than virgin plastic, yet the federal approval process to use it in food packaging is lax and leaving consumers at risk, researchers say.

Recycld content in food packaging is increasing as sustainability advocates press manufacturers to cut their use of virgin plastic.

Since 1990, the U.S. Food and Drug Administration (FDA), the agency responsible for ensuring food contact materials are safe, approved at least 347 voluntary manufacturer applications for food contact materials made with recycled plastic, according to a database on its website. Approvals have tripled in recent years, from an average of 7 to 8 per year through 2019, to 23 per year since then, and they continue to climb. The FDA has already approved 27 proposals through June this year. Plastics recycling

Other than Coca-Cola, most manufacturers seeking approval are petrochemical giants such as Eastman Chemicals, Dupont and Indorama; and lesser-known plastic packaging manufacturers, including many from China, India and other countries.

The end buyers of the recycled materials aren’t included in the FDA database, but many popular brands are using recycled content. Cadbury chocolate bars come in a wrapper marketed as 30% percent recycled “soft plastic packaging.” The Coca-Cola Co. in North America reports it sells soft drinks in 100% percent recycled PET (polyethylene terephthalate) bottles, while General Mills says its Annie’s cereal boxes use a liner made from 35% percent recycled plastic film.

Increasing recycled content in packaging may be good news for the planet, but researchers say the FDA has a lax approval process for plastic food packaging that hasn’t kept pace with the science on chemical hazards in plastics. Plastics recycling

More…

Invista Kingston site earns ISCC PLUS certification

INVISTA manufacturing site in Kingston, Ontario, Canada, has received International Sustainability & Carbon Certification (ISCC) PLUS certification of its processes to verify and validate bio, circular and bio-circular adipic acid and hexamethylene diamine (HMD) use. This achievement marks another major milestone in the company’s global strategy and reinforces a dedication to stewardship via environmental protection, social responsibility, and operational transparency. Plastics recycling

“We’ve listened to industry feedback and are proud to offer the option for ISCC PLUS certified nylon 6,6 polymers and fibers to our customers,” said Carl Brech, INVISTA executive vice president of Downstream Nylon. “This type of differentiated offering is another tool that can help them with their environmental goals.”

ISCC PLUS is a global certification system that verifies the sourcing and traceability of bio, circular, and bio-circular* products applying a mass-balance approach. It validates consistency with environmental, social, and governance criteria throughout the supply chain, and it provides assurance to consumers and stakeholders regarding the production practices and use of resources. Plastics recycling

More…

Plastics recycling

Nuclear – PS resins buck trends with slight price drop as other materials climb 20-08-2024

Bioplastics specialist builds PHA pilot plant in the Netherlands / Construction of commercial extraction plant planned

Bioplastics specialist builds PHA pilot plant in the Netherlands / Construction of commercial extraction plant planned