Bio-Polymers – Avantium N.V., a prominent company specializing in renewable and circular polymer materials, has announced the official opening ceremony for its FDCA Flagship Plant on October 22, 2024, in Delfzijl 28-06-2024

Bio-Polymers

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Fulgar Launches Q-GEO Biobased Polyamide Yarn

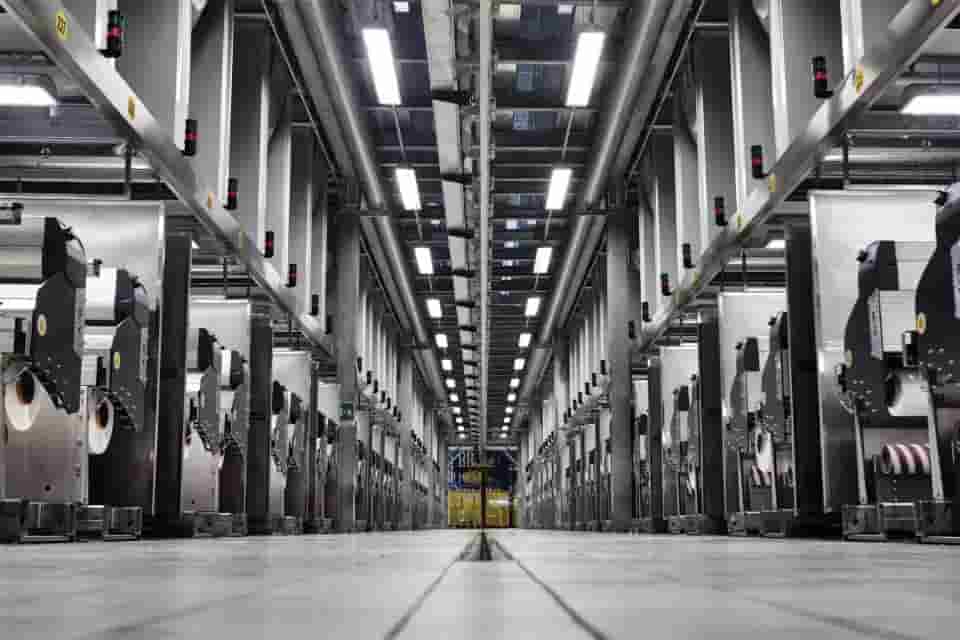

Fulgar, an innovative Italian company dedicated to environmental sustainability, has unveiled Q-GEO, a new biobased polyamide yarn poised to transform the textile industry. This yarn aligns with the rising demand for eco-friendly, advanced fabrics, making it ideal for large-scale ecological production.

The textiles and clothing industries are increasingly adopting next-generation materials—manmade polymers that are recyclable and derived from renewable sources. These materials aim to reduce reliance on fossil fuels, supporting the fashion industry’s shift towards sustainable practices with minimal environmental impact. Bio-Polymers

Q-GEO represents a significant advancement in Fulgar’s pursuit of combining natural fibre benefits with high-tech yarn performance. Unlike traditional polyamides, Q-GEO is 46% biobased, produced from non-edible corn deemed unfit for nutritional use. This corn is grown on land unsuitable for food crops, reducing environmental impact by minimizing water usage and greenhouse gas emissions compared to traditional cotton and standard polyamide production.

This innovative yarn offers several technical advantages. It provides the comfort of traditional polyamides while featuring superior body humidity management with 50% greater absorbency and enhanced breathability. Bio-Polymers

Q-GEO maintains the durability and toughness expected of polyamides, with additional benefits like ultra-rapid drying and flame-retardant properties without additives.

Q-GEO is certified under Oeko-Tex Std 100 Class I appendix 6 and Din Certco, following the ASTM D 6866:2022 R.N 8C376 method. An LCA (Life Cycle Assessment) study confirms Fulgar’s commitment to a transparent and sustainable supply chain, reinforcing its leadership in eco-friendly textile innovation. Bio-Polymers

Avantium N.V., a prominent company specializing in renewable and circular polymer materials, has announced the official opening ceremony for its FDCA Flagship Plant on October 22, 2024, in Delfzijl

Invited guests will receive invitations for this significant event. Additionally, Avantium will host an Avantium Retail Investor Day on October 23, 2024, allowing interested shareholders to tour the FDCA Flagship Plant.

Avantium focuses on innovative technologies for producing materials from sustainable carbon feedstocks, including biomass and CO2. Bio-Polymers

Their YXY® Technology converts plant-based sugars into furandicarboxylic acid (FDCA), a crucial component of the sustainable plastic PEF (polyethylene furanoate).

Avantium has successfully demonstrated this technology at its pilot plant in Geleen, the Netherlands, and is currently constructing the world’s first commercial FDCA plant in Delfzijl.

The company also provides R&D solutions in sustainable chemistry and offers advanced catalyst testing services.

Avantium collaborates with like-minded companies globally to advance renewable chemistry solutions. Bio-Polymers

Avantium’s shares are listed on Euronext Amsterdam and Euronext Brussels (symbol: AVTX), and the company is part of the Euronext Amsterdam SmallCap Index (AScX). Its headquarters are in Amsterdam, the Netherlands

The Internet of Things Revolutionises Packaging

The Internet of Things (IoT) has and is transforming very different industries, and packaging is no exception. Connected packaging, empowered by IoT technology, is reshaping how brands interact with consumers and manage their supply chains. This innovative approach bridges the gap between physical products and the digital realm, offering unprecedented opportunities for engagement, traceability, and sustainability.

Enhanced Consumer Engagement

Connected packaging leverages IoT sensors and smart labels to create interactive experiences for consumers. Bio-Polymers

By scanning a QR code or tapping an NFC tag, customers can access product information, authenticity verification, usage instructions, etc. This direct line of communication allows brands to forge stronger connections with their audience, providing value beyond the physical product.

For instance, a wine bottle scan might offer food pairing suggestions, exclusive discounts, or even a description of vineyard history. A pharmaceutical package could provide dosage reminders or side effect information. These interactions inform and engage consumers and generate valuable data for brands to refine their marketing strategies and product offerings. Bio-Polymers

ORNL nanofibers research strengthens bridge between fiber, matrix

A novel technique of depositing thermoplastic nanofibers enhancing their strength, toughness and ability to withstand stress, removing the need for traditional methods like coatings.

Scientists at the Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) have developed a method that demonstrates how fiber-reinforced polymer composite materials used in the automotive, aerospace and renewable energy industries can be made stronger and tougher to better withstand mechanical or structural stresses over time. Bio-Polymers

While composites already have many advantages, they are vulnerable to damage from strain because two diverse materials — rigid fibers and a soft matrix, or a binder substance — are combined to make them. According to ORNL, the interphase between the two materials needs to be improved because of its influence on the overall mechanical properties of composites.

ORNL’s Sumit Gupta says the research team deposited thermoplastic nanofibers like cobwebs to chemically create a supportive network that toughens the interphase. Their technique differs from conventional methods of coating the fiber surfaces with polymers, or providing a rigid scaffolding to improve bonding between the fiber and the matrix, which have been shown to be inefficient and expensive. Bio-Polymers

Germany’s ColorDigital launches DMIx SamplR for material digitisation

INSIGHTS

- DMIx by ColorDigital GmbH introduces the DMIx SamplR, a revolutionary hardware device for creating digital material twins with one-touch simplicity.

- Utilising advanced Apple iPhone technology, it provides high-quality scans and instant 3D previews.

- Integrated into the DMIx platform, it streamlines remote texture development and comprehensive texture mapping.

DMIx by ColorDigital GmbH announces the launch of DMIx SamplR, a cutting-edge hardware device designed to simplify and enhance the process of creating digital material twins. Bio-Polymers

Designed to meet the needs of professionals in the fashion, footwear, automotive, and architecture industries, the DMIx SamplR promises to revolutionize the way materials are digitized, communicated and managed.

This innovative scanner represents a significant advancement in the field of digital product creation (DPC), offering unparalleled accuracy, functionality and interaction for professionals in product sourcing and development. Bio-Polymers

“One Touch – Digital Twin Collaboration”

At the heart of the DMIx SamplR is its remarkable ease of use. With just one button, users can create precise digital replicas of flat physical materials. This device integrates advanced Apple iPhone technology and unique lighting, offering high-quality scans at 300 PPI. The result is an effortless, accurate color scan that seamlessly integrates into the DMIx platform.

Solid Economy Provides Boost to Chemical Production

- Recession risks have moderated; consumer spending and investment continue to propel the U.S. economy

- Demand for chemicals is recovering; inventories in a more balanced position across the supply chain

- S. production remains competitively advantaged due to shale and new investments in chemistry-containing clean technologies, but strong regulatory headwinds remain a threat. Bio-Polymers

Looking ahead the U.S. economy will drive up demand across many key chemistry end-use industries, which should tee up a healthy increase in chemical output. This promising outlook is dampened by the rising regulatory impact on the chemical industry, which threatens to undermine America’s competitive advantages in energy and the potential growth generated by the rebound in U.S. manufacturing.

Economy Maintains Momentum

Moving into mid-year, the U.S. economy is on solid footing. While Q1 GDP came in weaker than expected, it was softer net exports and inventory investment that offset stronger activity in the domestic economy. Inflation unexpectedly accelerated in Q1 before resuming its downward trend and expectations for interest rate cuts have likely been pushed back toward the latter part of the year. We expect U.S. GDP to rise 2.4% in 2024, before slowing to a 1.7% gain in 2025. Bio-Polymers

Consumer spending has remained relatively resilient thus far in 2024 on rising real wages and confidence in the labor market.

Bio-Polymers